Mechatronics Research Lab Publications

List still being populated due to webpage maintenance

2014

D Chatzigeorgiou; K Youcef-Toumi; R Ben-Mansour

Design of a Novel In-Pipe Reliable Leak Detector Journal Article

In: IEEE/ASME Transactions on Mechatronics, vol. 20, no. 2, pp. 824-833, 2014, ISSN: 1941-014X.

Abstract | Links | BibTeX | Tags: Control Theory, Experimentation, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation

@article{MRL_AFM_Leak_Detector,

title = {Design of a Novel In-Pipe Reliable Leak Detector},

author = {D Chatzigeorgiou and K Youcef-Toumi and R Ben-Mansour},

url = {https://ieeexplore.ieee.org/document/6778062?arnumber=6778062},

doi = {10.1109/TMECH.2014.2308145},

issn = {1941-014X},

year = {2014},

date = {2014-03-25},

journal = {IEEE/ASME Transactions on Mechatronics},

volume = {20},

number = {2},

pages = {824-833},

publisher = {IEEE},

abstract = {Leakage is the major factor for unaccounted losses in every pipe network around the world (oil, gas, or water). In most cases, the deleterious effects associated with the occurrence of leaks may present serious economical and health problems. Therefore, leaks must be quickly detected, located, and repaired. Unfortunately, most state-of-the-art leak detection systems have limited applicability, are neither reliable nor robust, while others depend on the user experience. In this paper, we present a new in-pipe leak detection system. It performs autonomous leak detection in pipes and, thus, eliminates the need for the user experience. This paper focuses on the detection module and its main characteristics. Detection in based on the presence of a pressure gradient in the neighborhood of the leak. Moreover, the proposed detector can sense leaks at any angle around the circumference of the pipe with only two sensors. We validate the concepts by building a prototype and evaluate the system's performance under real conditions in an experimental laboratory setup.},

keywords = {Control Theory, Experimentation, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation},

pubstate = {published},

tppubtype = {article}

}

2012

Rached Ben-Mansour; Kabir Suara; Kamal Youcef-Toumi

Determination of important flow characteristics for leak detection in water pipelines-networks Journal Article

In: Computational Thermal Sciences, vol. 5, pp. 143-151, 2012, ISSN: 143-151.

Abstract | Links | BibTeX | Tags: Control Theory, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation, Simulation

@article{MRL_AFM_Flow_Leak_Detection,

title = {Determination of important flow characteristics for leak detection in water pipelines-networks},

author = {Rached Ben-Mansour and Kabir Suara and Kamal Youcef-Toumi},

url = {http://www.dl.begellhouse.com/journals/648192910890cd0e,1c6ade0932d1248e,18dcce9156c09e65.html},

doi = {10.1615/ComputThermalScien.2013006301},

issn = {143-151},

year = {2012},

date = {2012-07-16},

journal = {Computational Thermal Sciences},

volume = {5},

pages = {143-151},

publisher = {begellhouse},

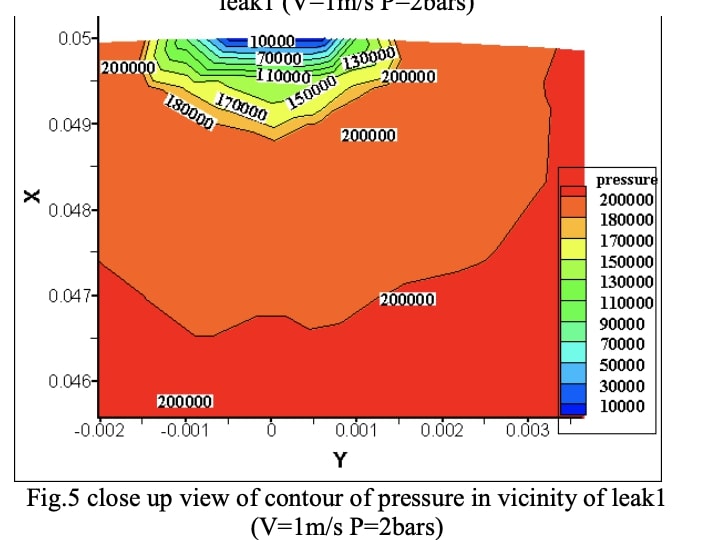

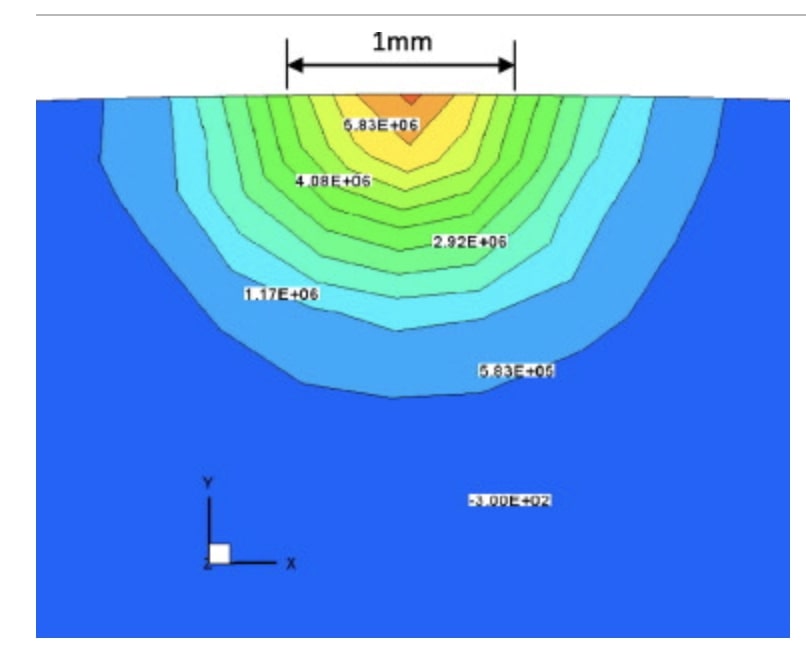

abstract = {The accuracy of a leak detection method depends greatly on the flow and leak parameters in a given pipeline. This paper gives some insight into the flow characteristics around simulated small leaks. The present computational fluid dynamics (CFD) studies have indicated clear distinctive features in fluid pressure and fluid acceleration that can be used for the early detection of small leaks (<1 of the total flow) in water distribution pipelines. The present CFD simulations based on a steady state standard к − ε turbulent flow model are carried out for different pressure lines in 4 in. (100 m) ID pipe. Based on these simulations, it has been found out that the pressure gradients in the vicinity of the leaks are quite large, hence a leak detection method based on pressure gradient measurement is proposed. In addition, these simulations have shown remarkable gradients in the axial flow acceleration along the centerline of the pipe. These discovered flow features can offer another leak detection method based on the use of accelerometers.},

keywords = {Control Theory, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation, Simulation},

pubstate = {published},

tppubtype = {article}

}

R Ben-Mansour; M A Habib; A Khalifa; K Youcef-Toumi; D Chatzigeorgiou

Computational fluid dynamic simulation of small leaks in water pipelines for direct leak pressure transduction Journal Article

In: Computers & Fluids, vol. 57, pp. 110-123, 2012, ISSN: 0045-7930.

Abstract | Links | BibTeX | Tags: Control Theory, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation, Simulation

@article{MRL_AFM_Dynamic_Simulation_Leak_Pipe,

title = {Computational fluid dynamic simulation of small leaks in water pipelines for direct leak pressure transduction},

author = {R Ben-Mansour and M A Habib and A Khalifa and K Youcef-Toumi and D Chatzigeorgiou},

url = {https://www.sciencedirect.com/science/article/pii/S0045793011003884},

doi = {https://doi.org/10.1016/j.compfluid.2011.12.016},

issn = {0045-7930},

year = {2012},

date = {2012-03-30},

journal = {Computers & Fluids},

volume = {57},

pages = {110-123},

publisher = {Science Direct},

abstract = {Computational fluid dynamic simulation of small leaks in a pipe having 0.1m diameter has been performed under realistic velocities and pressures using a 3D turbulent flow model of well tested CFD code. The steady state simulations have shown clear signature in the pressure and pressure gradient variations along the pipe. For very small leaks (below 1l/min), this signature in not very strong in the pressure variation, but very clear in the pressure gradient. The averaged power spectral density (PSD) as well as FFT of the pressure fluctuations based on transient Detached Eddy Simulations (DESs) are presented for different locations around the leak position. These results show that the presence of a leak causes measurable differences in the magnitude and frequency of the pressure signal spectrum and also in the averaged PSD for the range of 220–500Hz frequency.},

keywords = {Control Theory, Inspection, Physical System Modeling, repair & intelligence for water distribution pipes, Robotics & Automation, Simulation},

pubstate = {published},

tppubtype = {article}

}